Different Types of Grinding Wheels

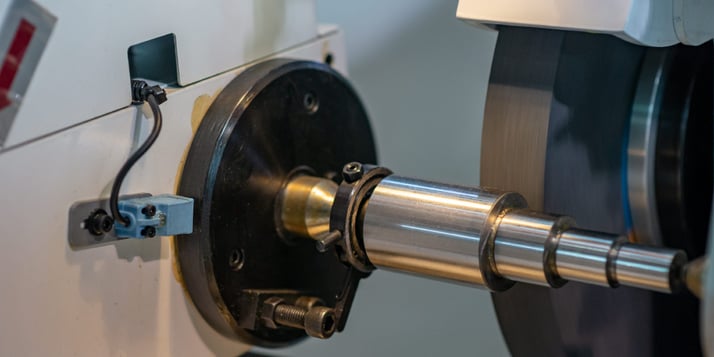

When you craft and machine your aerospace parts, getting the high quality you demand and require comes down to the ability to grind and finish the parts so they perform the job they need to perfectly every time. How is it done? Grinding is a proven technique that instantly improves your parts, but there is always one key question that must be asked. What type of grinding wheel should be used to get the job done?

Click Here for our The State of Aerospace Manufacturing Infographic

Grinding wheels are an abrasive cutting tool with thousands of abrasive grains distributed around the wheel. These grains move against the workpiece to cut away any tiny chips that affect part performance. The diameters of wheels range from 1 to 20+ inches and can vary in thickness, down to a fraction of an inch. Different wheels are needed for different operations and different parts. For example, a small wheel might be perfect for a piece of auto body work while a larger wheel might be needed to grind down railroad tracks.

Let's get a bit more specific.

There are nine basic types of grinding wheels. Here's a rundown on each one and what they are used for:

-

Straight wheels. The most common wheel type, straight wheels are used for surface, cylindrical, and centerless grinding operations. They're used to create slightly concave surfaces.

-

Cylinder. Used in vertical and horizontal spindle grinders, cylinder--also called ring wheels--have no center mounting support and are used for creating flat surfaces by using the end face of the wheel.

-

Tapered wheels. Typically used for operations like threading and gear teeth, tapered wheels are similar to straight wheels, but they are tapered towards the center, so it can accept higher lateral loads.

-

Straight cup wheels. An alternative to cup wheels in tool and cutter grinders, the additional radial grinding surface is beneficial for certain types of work.

-

Dish cup wheels. Used for cutter grinding and jig grinding, dish cup grinding is a very shallow cup-style grinding wheel: the thinness allows grinding in slots and crevices.

-

Saucer wheels. Used for grinding twist drills and milling cutters, saucer wheels are common for non-machining areas.

-

Diamond wheels. When grinding extremely hard materials like carbide cutting tips, concrete, even gemstones, diamond wheels are up to the task.

-

Small mounted wheels. When mounted on a hand tool or steel mandrel, small mounted wheels come in all kinds of variations and are used for various operations

-

Cut-off wheels. Thin and using radial fibers for reinforcement, cut-off grinders are used on angle grinders for quick removal or trimming.

The type of grinding wheel you use is determined by a number of factors, including part material.

So, that covers the nine types of grinding wheels, but that isn't the end of our story. Grinding wheels are also defined by the abrasives that actually do the work of cutting away excess material. The percentages of grain and bond as well as their spacing on the wheel determines the wheel's structure. The particular abrasive is chosen based on how it interacts with the work material. Ideal abrasives stay sharp with minimal point dulling. When the points of the abrasives begin to dull, the abrasives fracture, creating new cutting points.

Cubic boron nitride (CBN) is a versatile superabrasive used to grind steel and nickel alloys. CBN may not be as hard as diamond, but it is much better at resisting wear, which means fewer wheel changes and less downtime for the machines while providing excellent thermal stability. Plating thickness is also important for CBN grain wear during grinding: thick coatings tend to hold grains better but don't remove material very quickly. Meanwhile, thin coatings remove material quickly but also lose grains faster.

There are other abrasives that can be used in grinding wheels, which is why you should consult with a grinding expert before beginning the finishing process in order to achieve the best-performing parts you need. At the end of the day, though, the wheel is only part of final performance. The stress-state of the abrasive is a result of thermal and mechanical wear, which is driven by a variety of factors. This is why it takes an expert hand and experience at the grinding wheel to yield the best results.